Installation Procedure

Only general hints are introduced here, because Johnson as manufacturer of the marble and quartz based engineered stone has no influence on the individual building conditions and performance. Characteristics of the Johnson engineered products being used must be consistent with characteristics of all other construction materials being used. The behavior of the Johnson engineered product after installation depends on the quality of the installation and fixation.

During installation it is necessary to pay special attention to the quality of the subfloor surface when carrying out joint-less installation of the floor and wall tiles. It is necessary to adhere to the preparation technology and production procedures given by the producers of the subfloor mixtures, adhesive, jointing materials and other construction chemicals used. After jointing is performed it is necessary to follow the correct procedure for product cleaning.

Precautions

- Engineered marble & quartz products are recommended for interior applications only.

- Prior to commencing installation, it is recommended that marble / quartz from several supply lots are laid on the floor under natural light to check color consistency.

- Company does not recommend using cement / mortar / POP for installation as these have a strong alkalinity. Prolonged exposure can cause permanent discoloration & loss in gloss of the product.

- Depending on the site conditions, equipments / methodology used and labour skill employed, gloss levels achieved during repolishing of engineered marble may be different as compared to factory finished polish.

- Company absolves itself of any responsibility due to complaints arising from improper handling, storage, installation or usage of its products other than what it is intended for.

- Recommended cut size for use: It is ideal to cut the slab of size 10ft X 4ft in 3 equal pieces. Else, at least use in 2 pieces of size 5ft x 4ft each, provided the thickness of the slab being used is 1.6cm or 18mm. In case of slab with 16mm thickness, the maximum recommended size per piece is 2ft x 2ft.

Installation Process

Adhesives

- For Johnson Marble & Quartz products, it is recommended to use adhesive (Diamond Star + Admix AD-1) from ARDEX ENDURA (INDIA) PVT LTD or any other polymer modified adhesives meeting these specifications. For more details of adhesive and technical assistance related to installation, please visit www.ardexendura.com or contact through e-mail on customercare@ardexendura.com

Under Tile & Stone Primer Application

- It is recommended to apply "Under Tile & Stone Primer" from ARDEX ENDURA (INDIA) PVT LTD or other equivalent product on back surface & side edges of marble & quartz slabs to prevent efflorescence.

Surface Preparation

- Remove all loose particles, mortar to reach out to a sound surface.

- Surface should be made free from dirt, dust and other contaminants.

- New screeds and plastering should be cured for minimum 7 days and dried completely for minimum 2 weeks or as per manufacturer's specification.

- Surface should be plain, plumb in line without undulations.

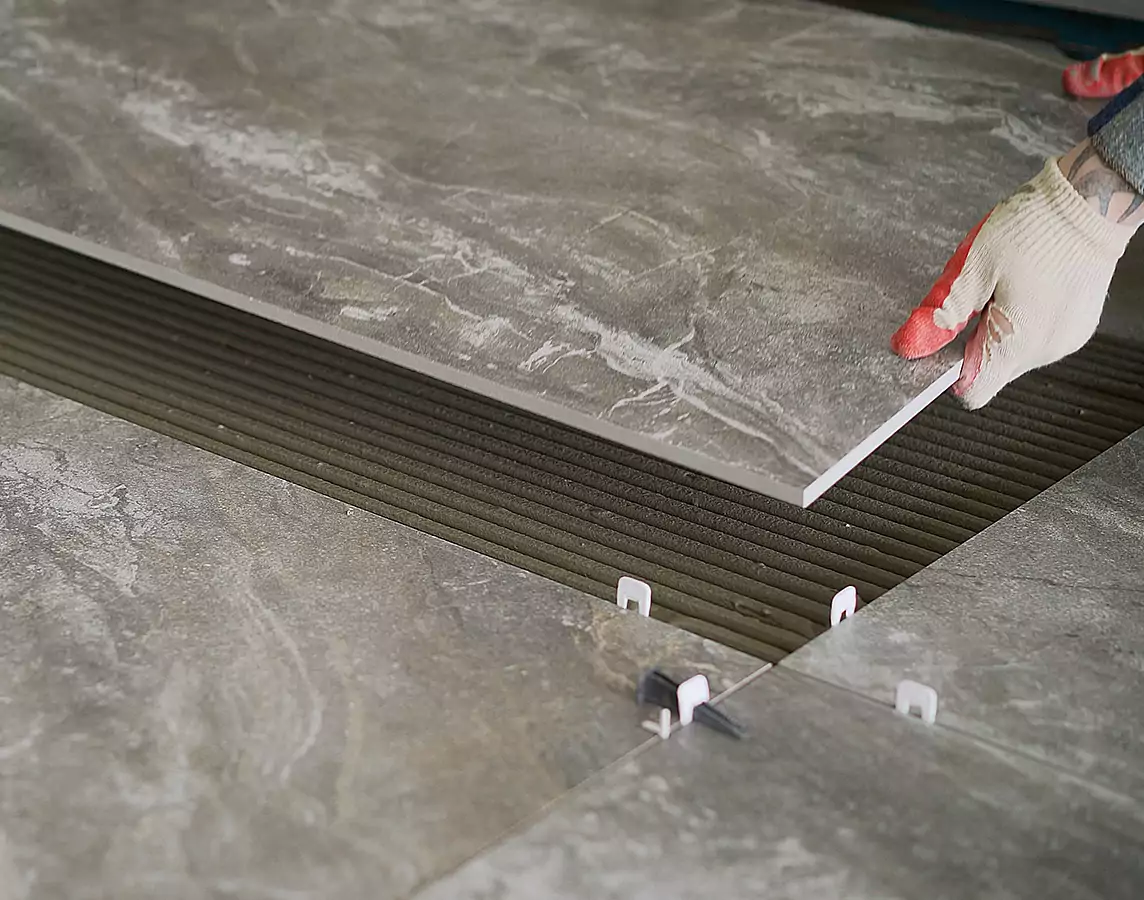

Application Of Adhesive & Installation

- Spread the adhesive on wall/floor surface at thickness of 0.2-0.6 cm using suitable steel notch trowel.

- Press the slab firmly into position with a slight twisting action and use suitable rubber mallet for gentle tamping.

- Depending on the span, it is recommended to provide expansion joints of min. 0.3- 0.5 cm at regular intervals during installation to facilitate thermal expansion; spacers of suitable thickness may be used followed by installing flexible polyurethane sealant of ARDEX ENDURA (INDIA) PVT LTD or other equivalent product with same specification.

- A gap of minimum 0.8 to 1 cm should be kept around the perimeter (under skirting) of laid marble/quartz flooring.

- Suitable support should be provided during the initial setting time to ensure proper adhesion to substrate.

- Know more about ARDEX ENDURA please click here.

Grouting

- Do not use cement / mortar / POP for grouting as these are alkaline. The reaction may cause patches on joints. Always use epoxy resin based grouts. Grouting can be carried out after 4-5 days of installation; company recommends grouts from ARDEX ENDURA (INDIA) PVT LTD or other equivalent epoxy resin based grouts.