Engineered Stone - Marble & Quartz Supplier

Adding uniqueness to every space, Johnson Marble & Quartz is a one-stop destination for industry-grade engineered stone of all sizes and scales. Johnson Marble & Quartz is a pioneering name in the distribution of top-class engineered stone for a wide range of applications -ranging from kitchen countertops to fireplaces, bathroom vanities, and so more. We offer one of the most impressive selections of top-quality exotic and world-famous engineered stone slabs across India and beyond.

What is Engineered Stone?

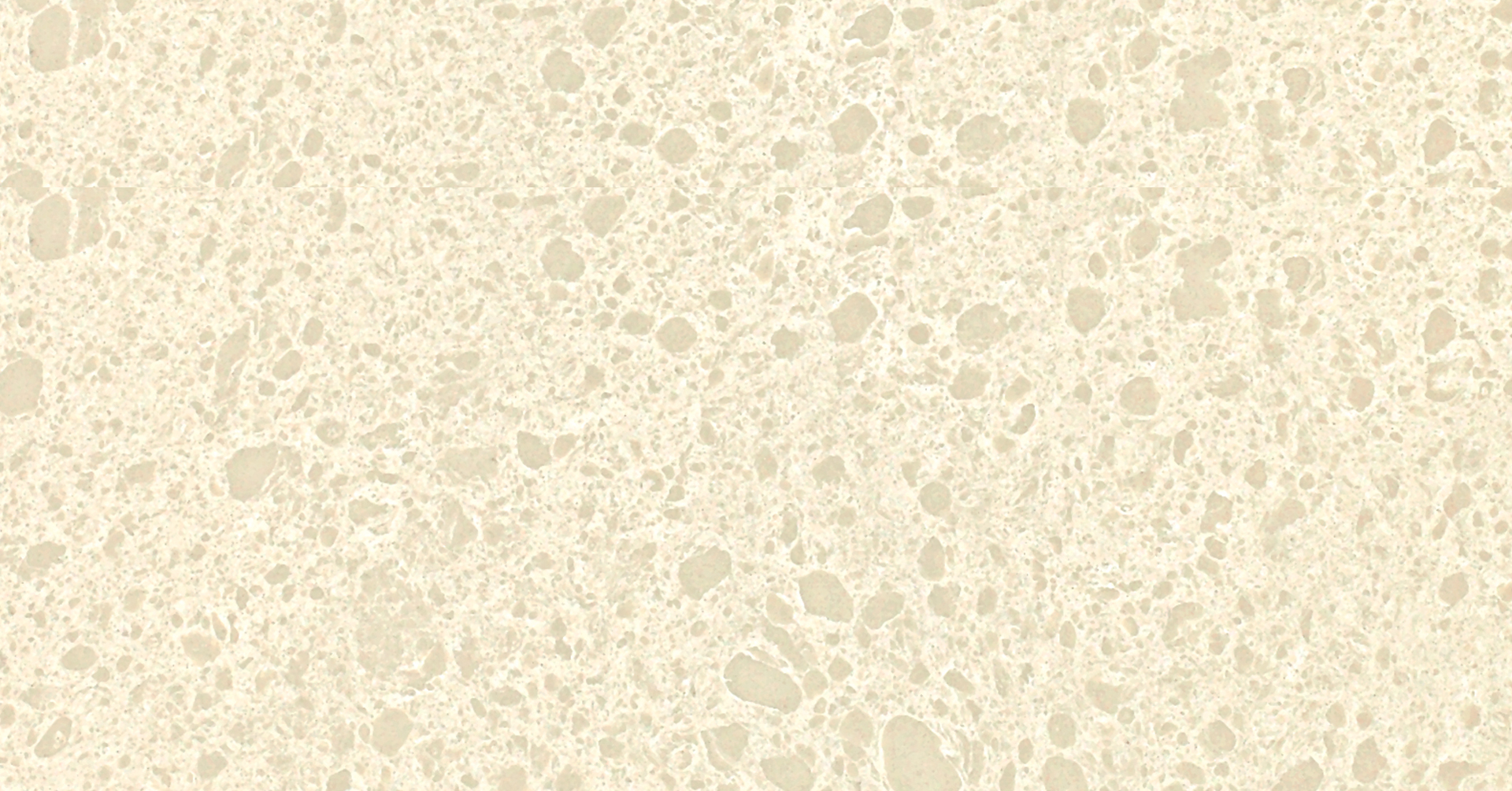

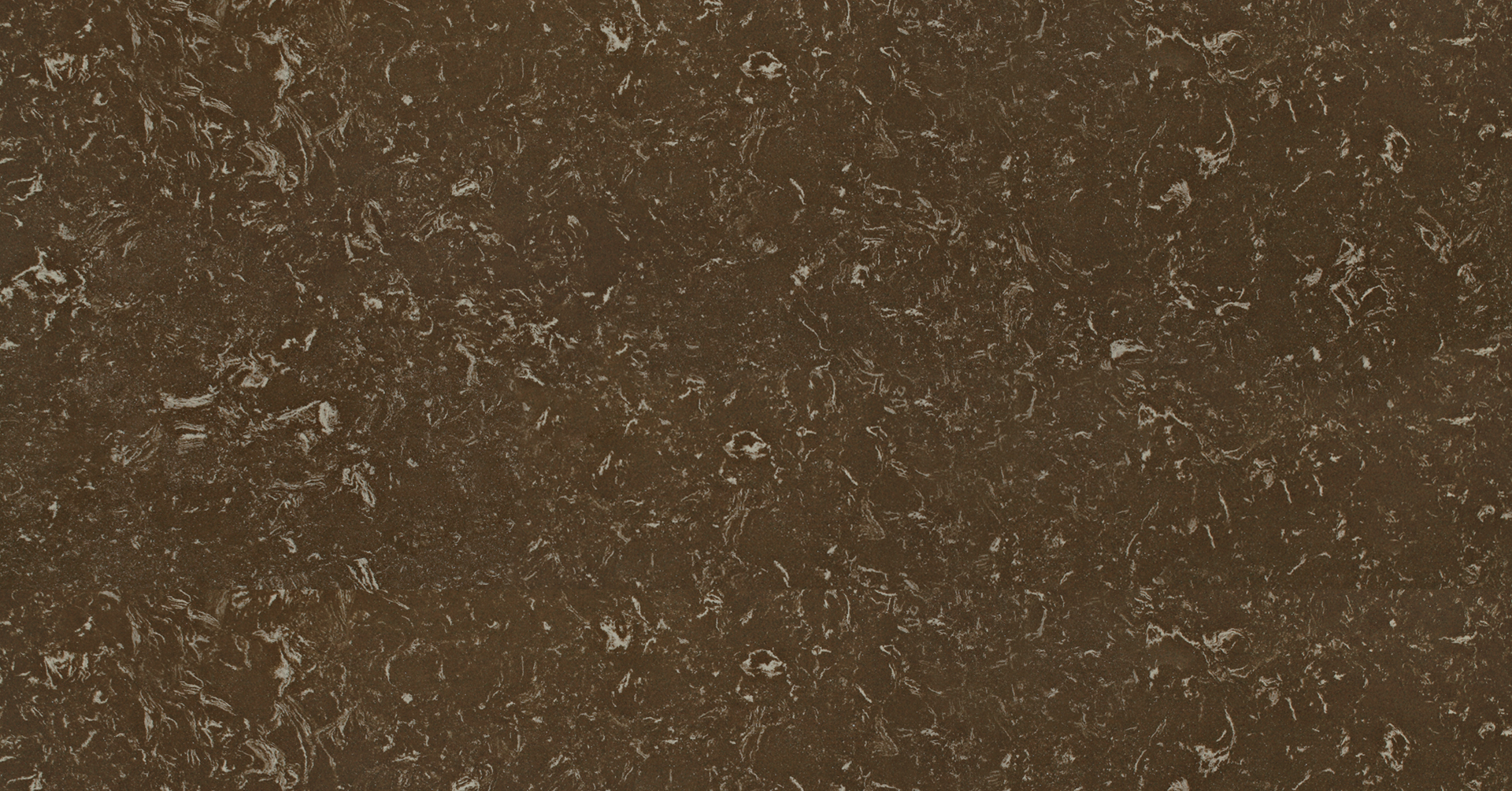

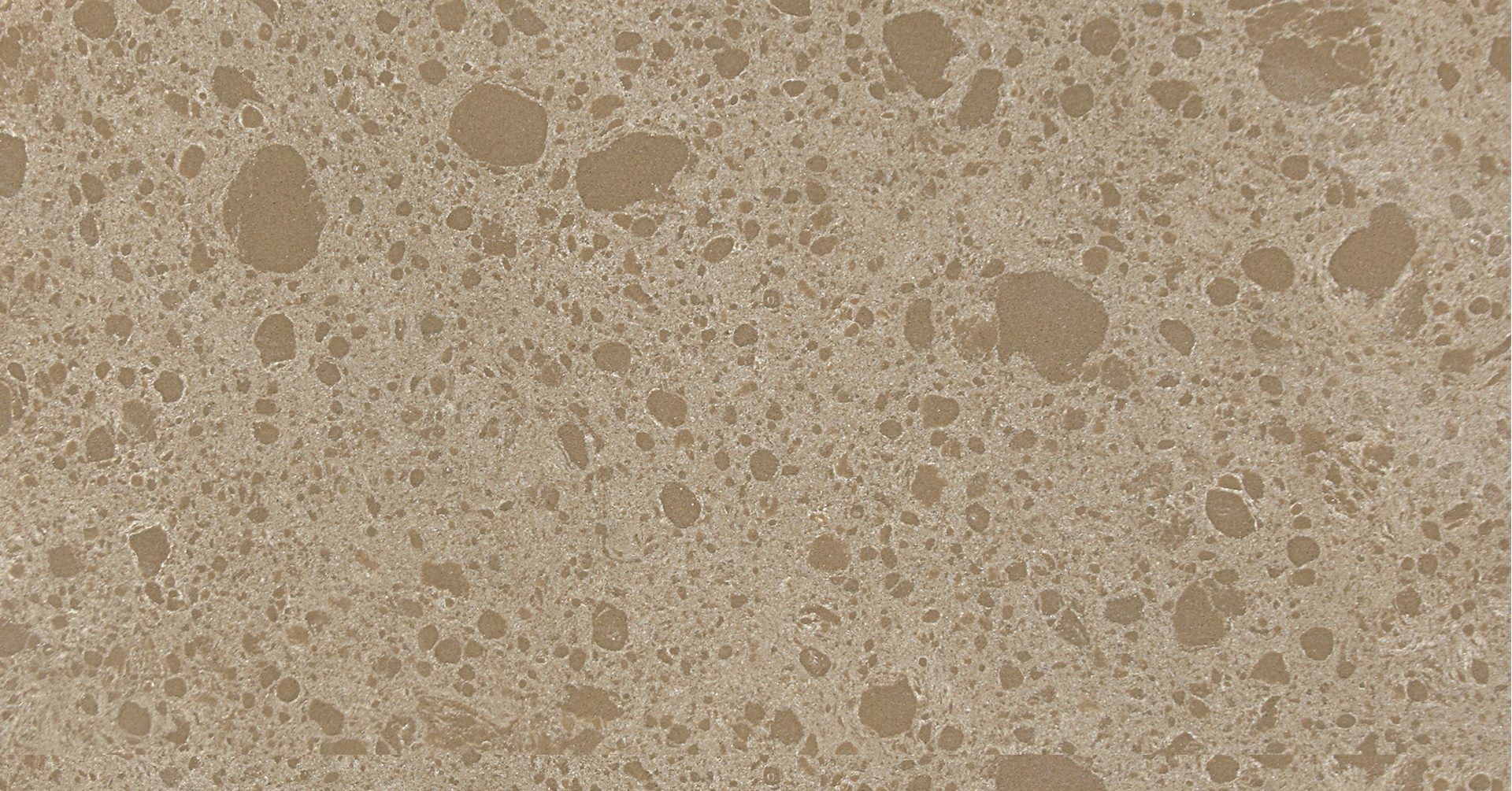

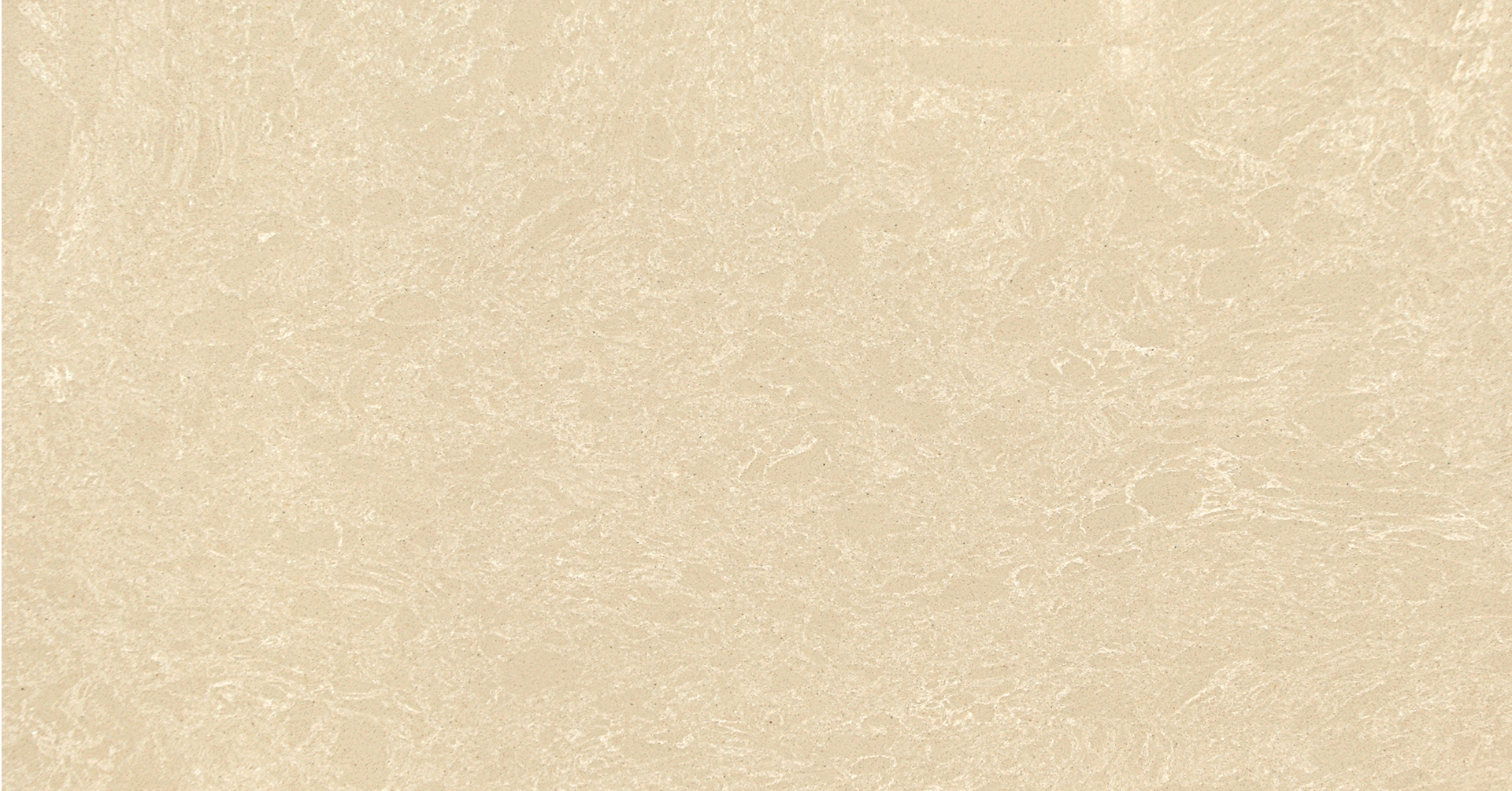

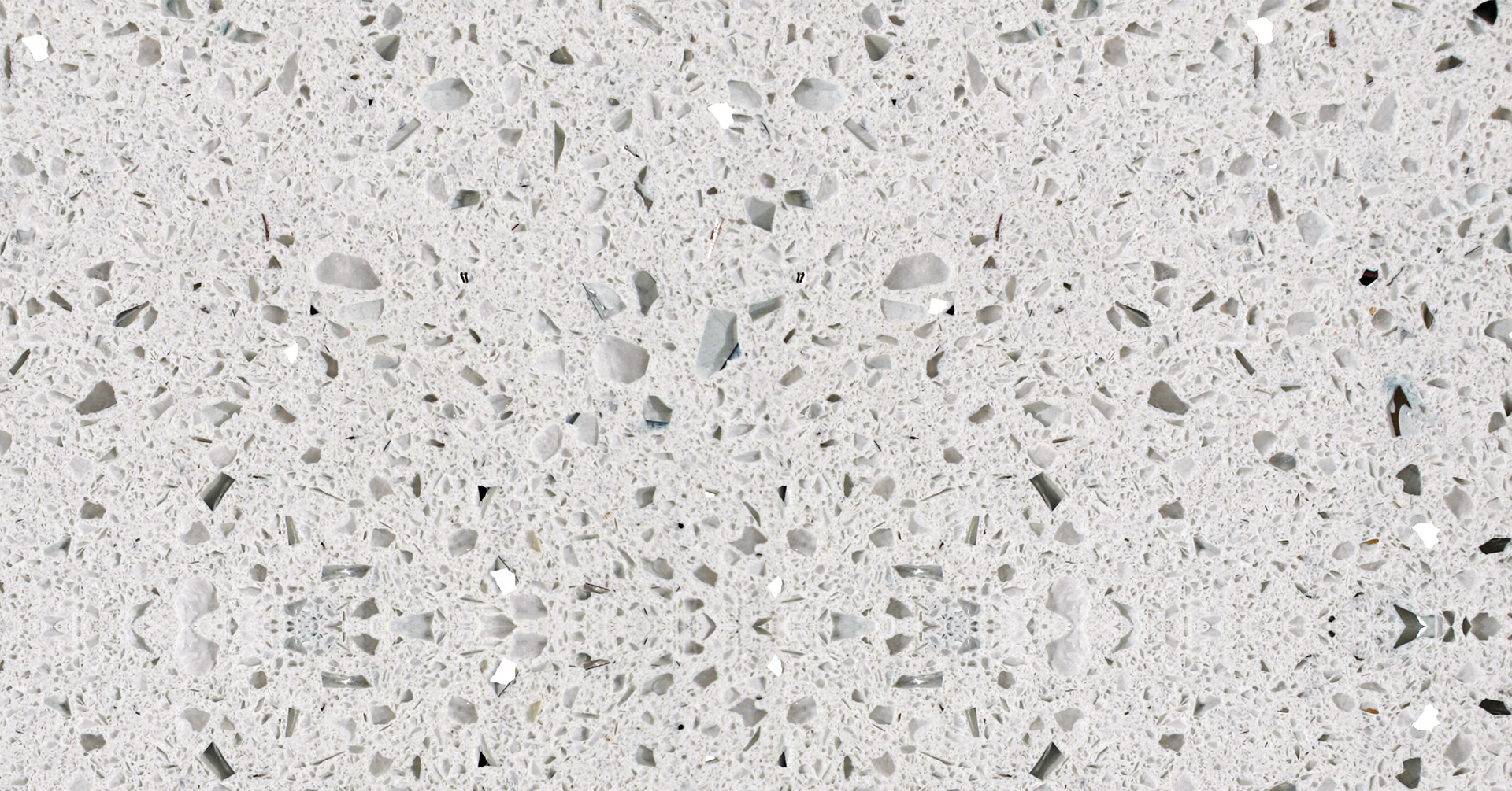

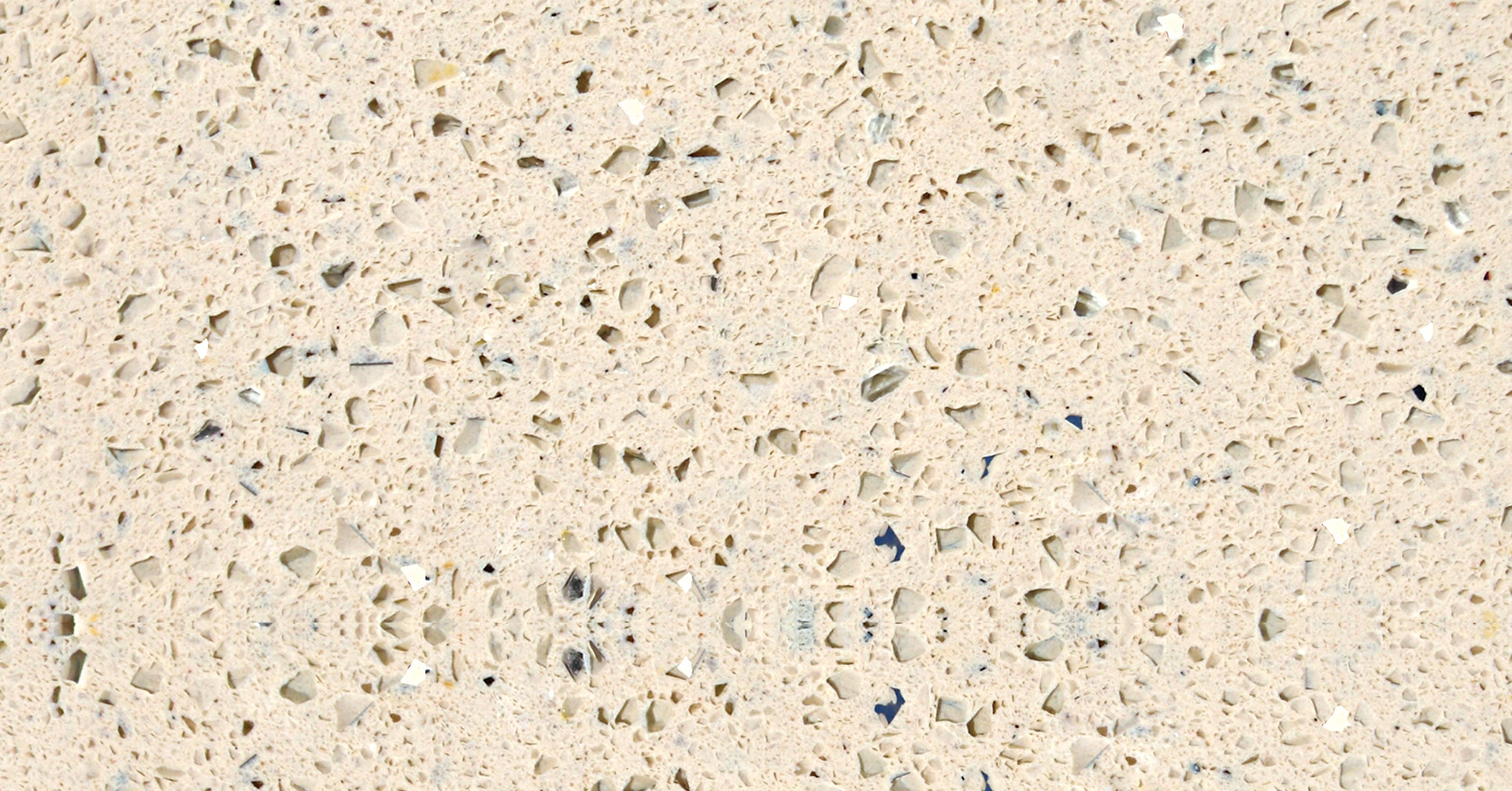

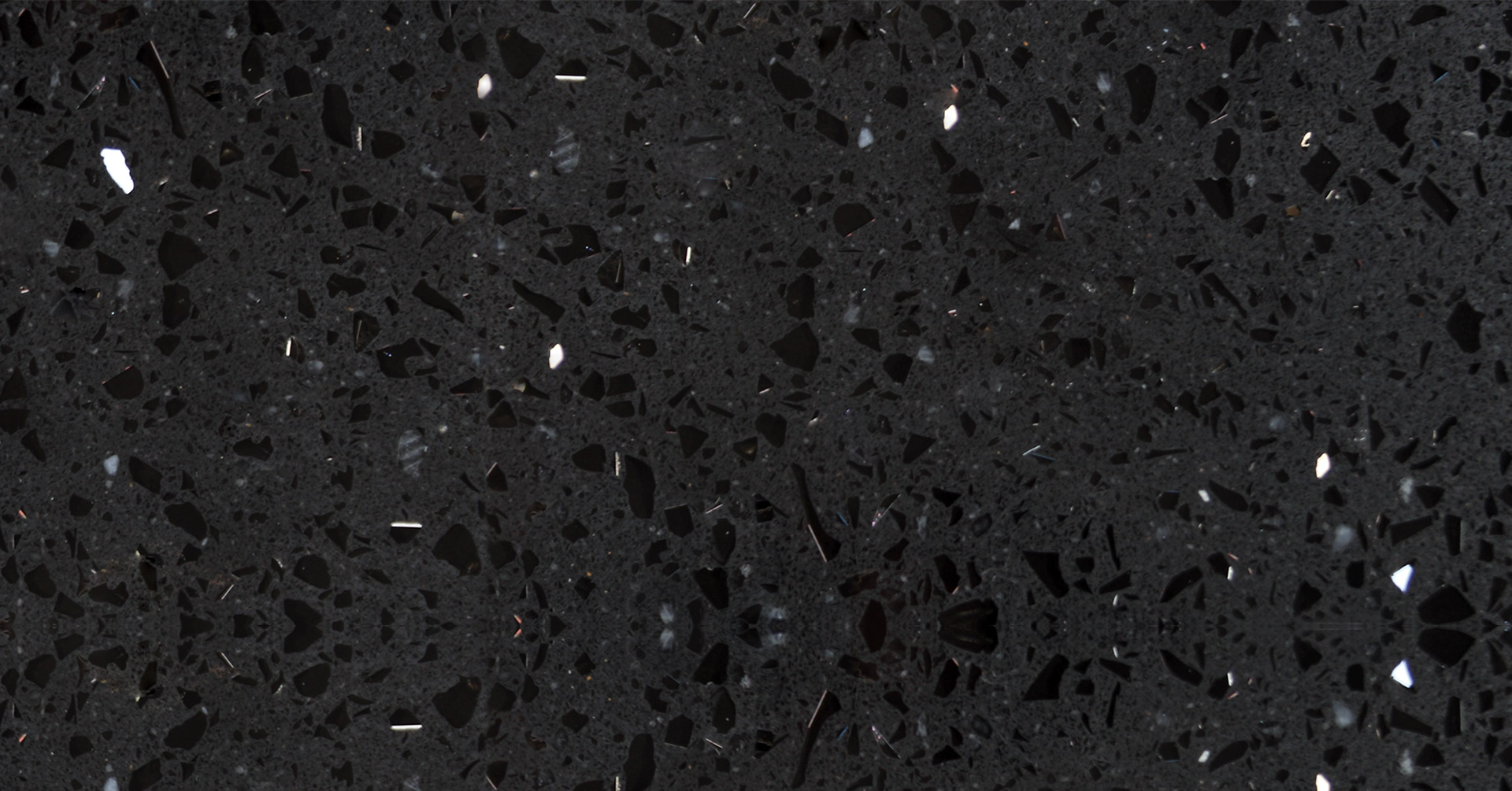

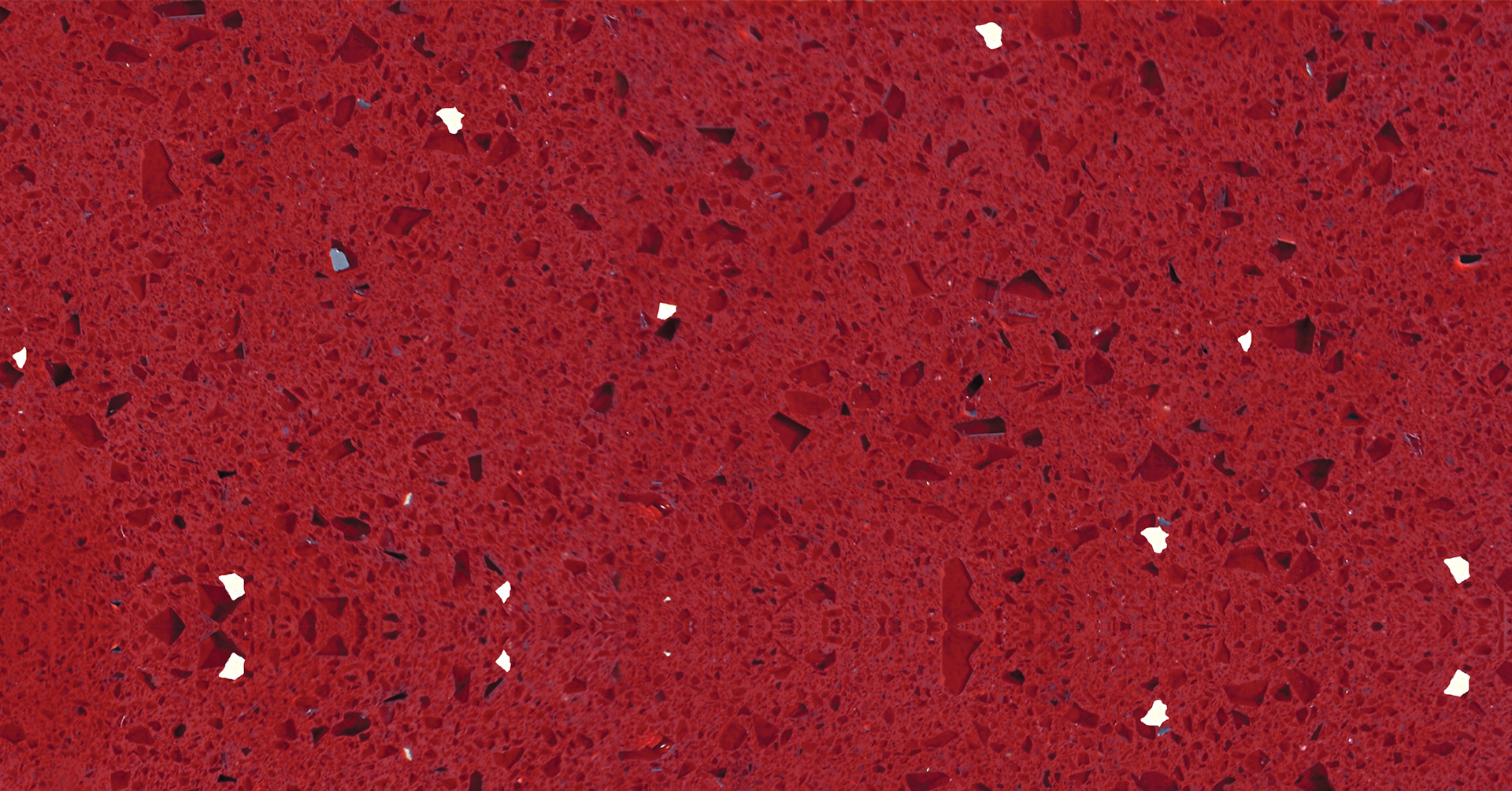

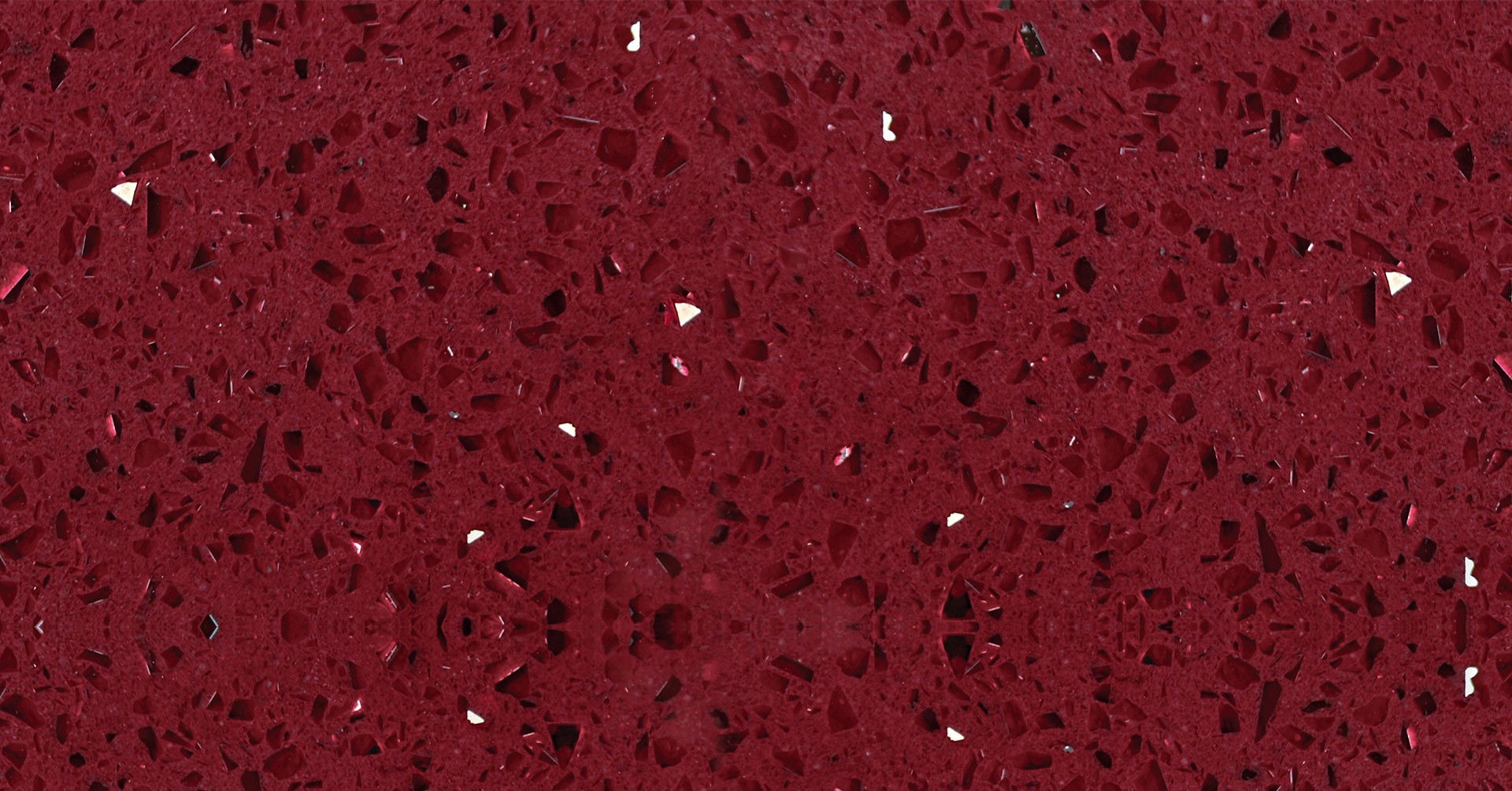

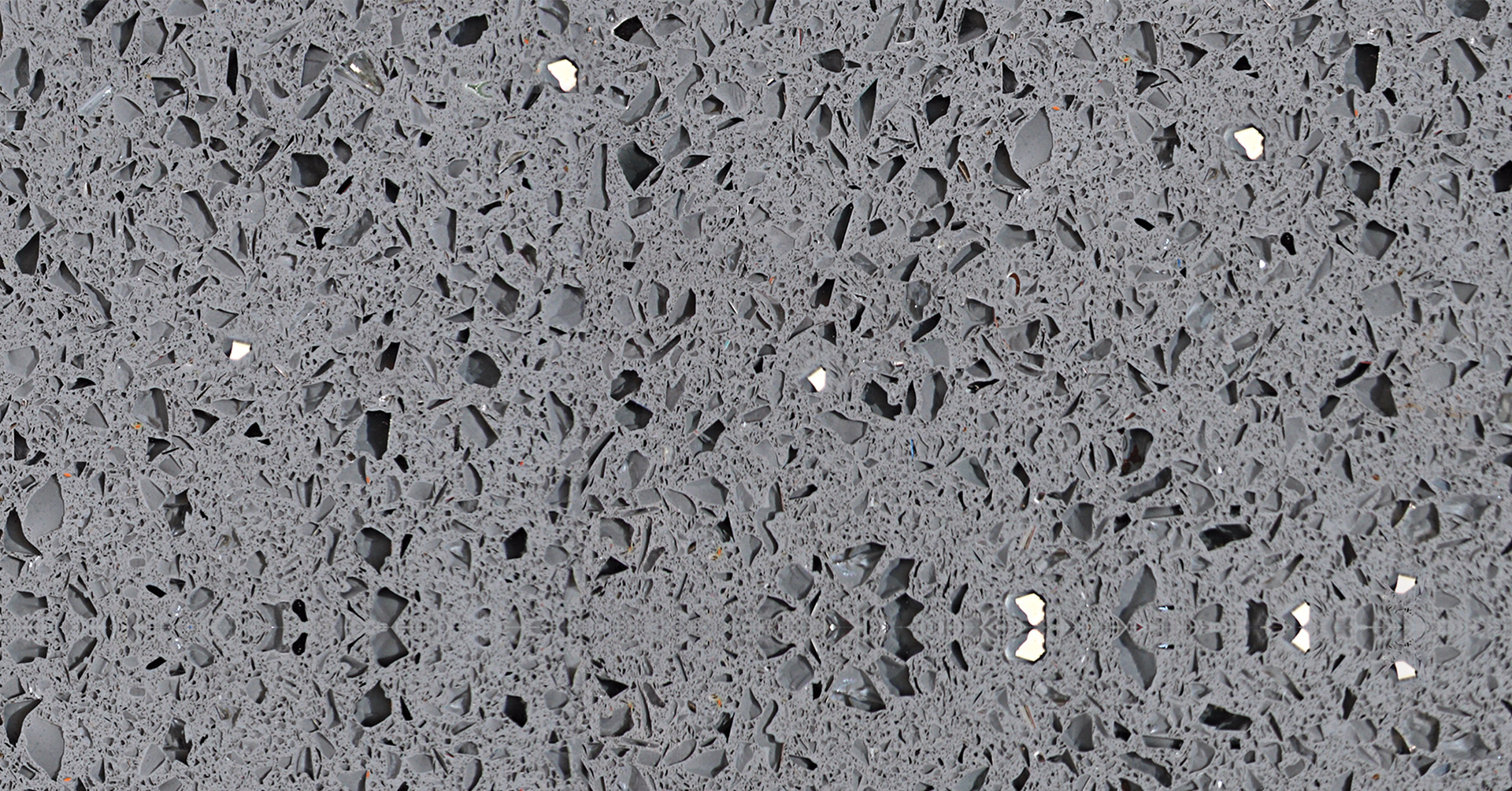

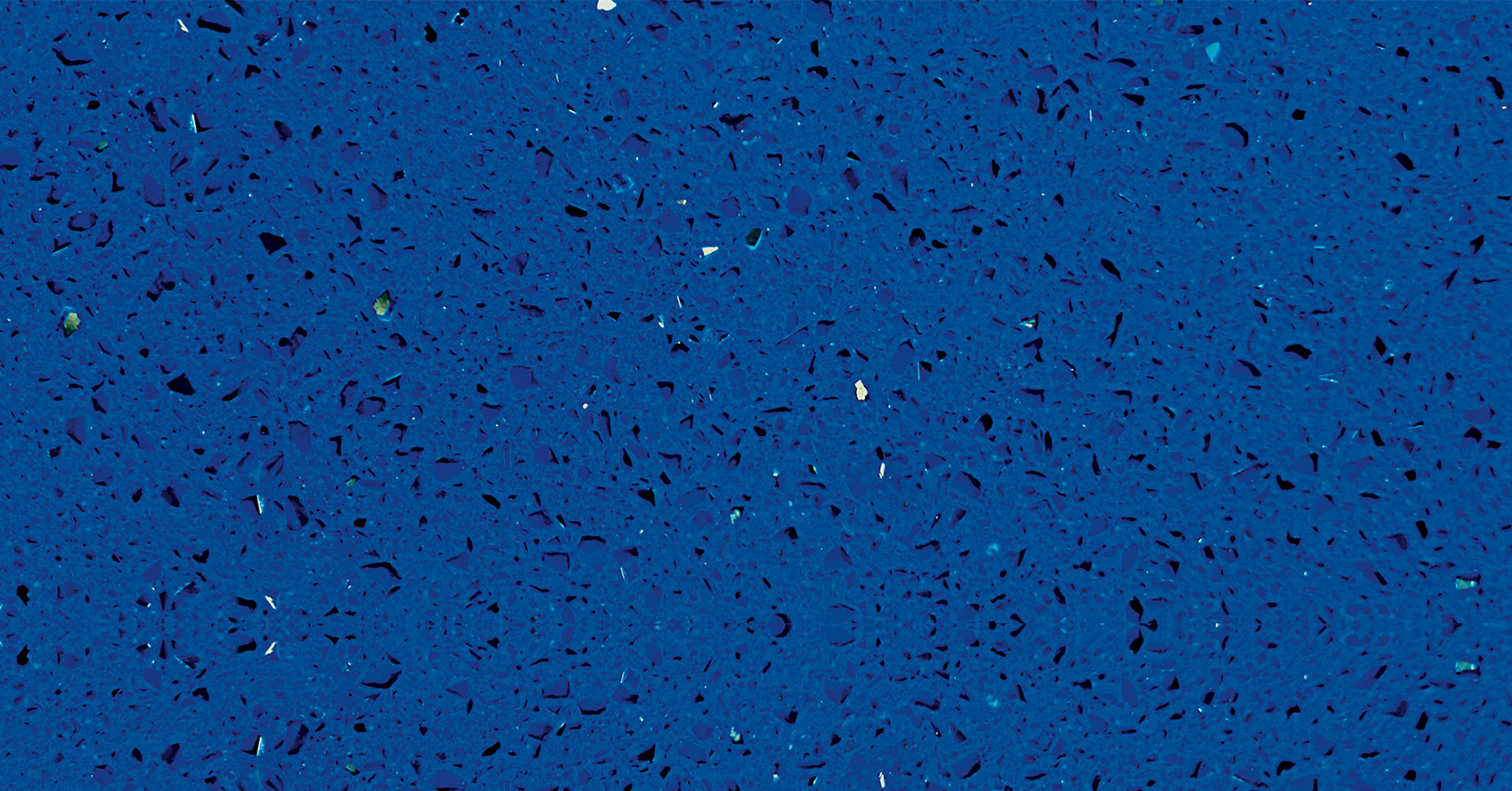

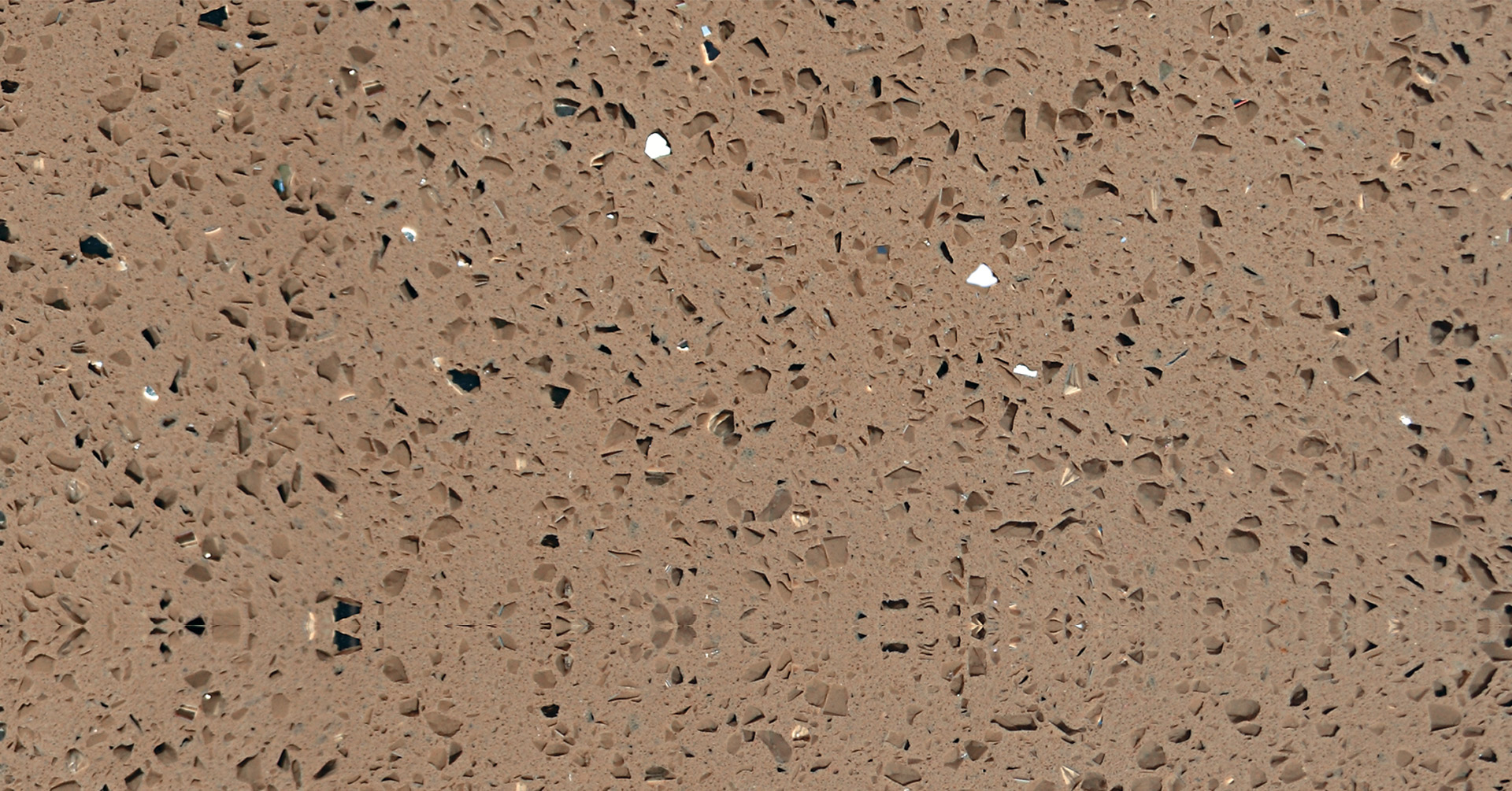

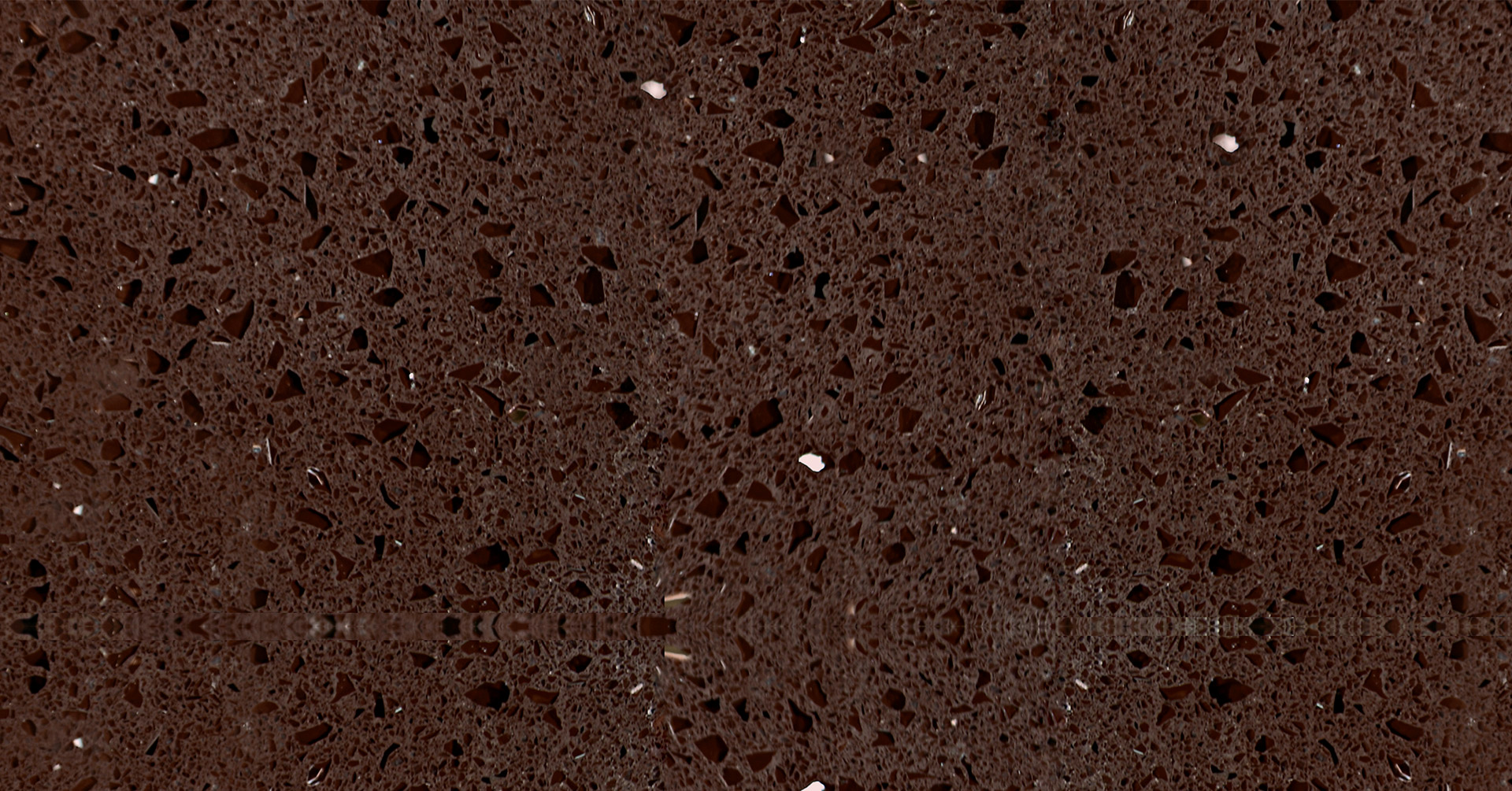

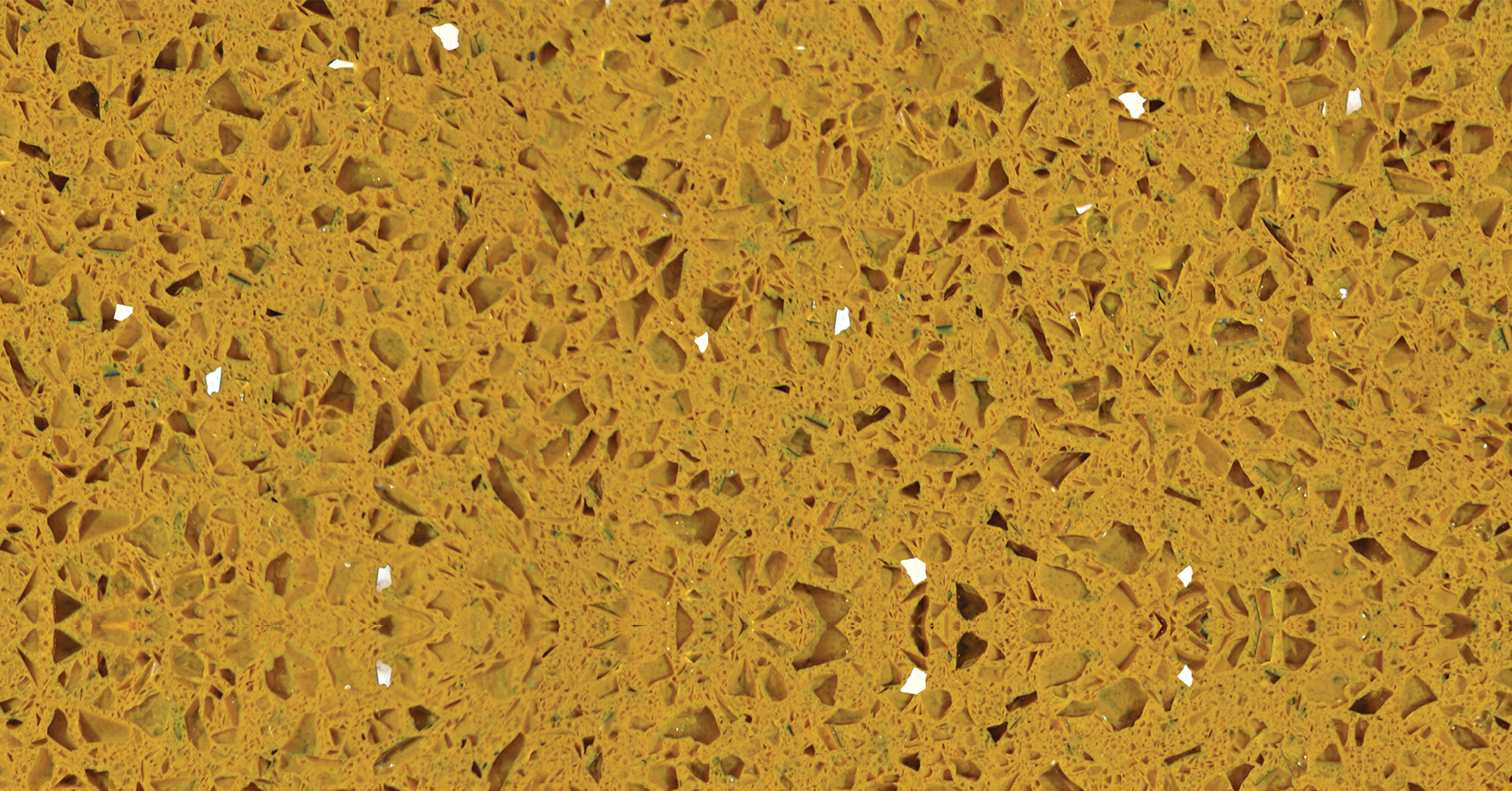

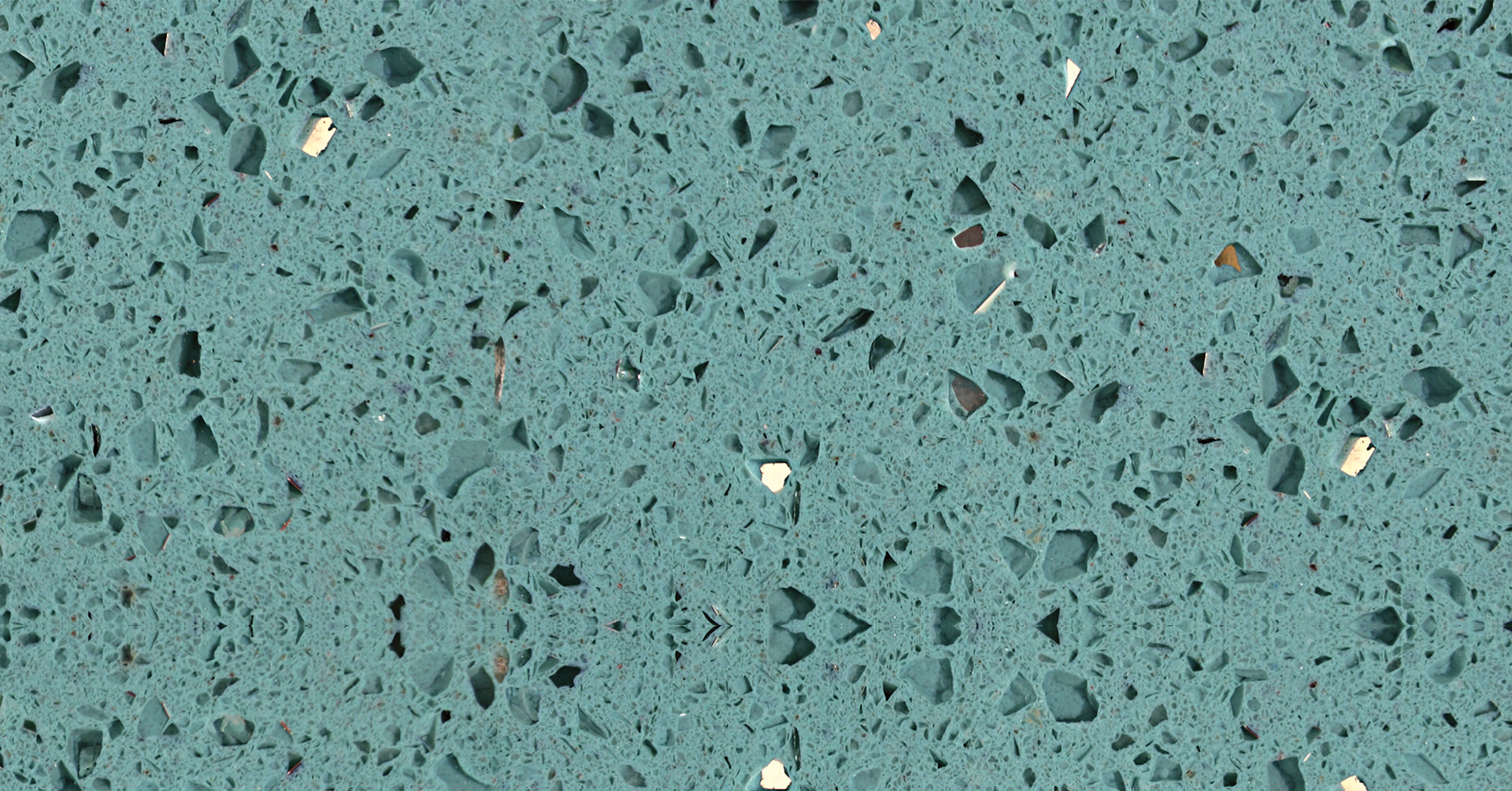

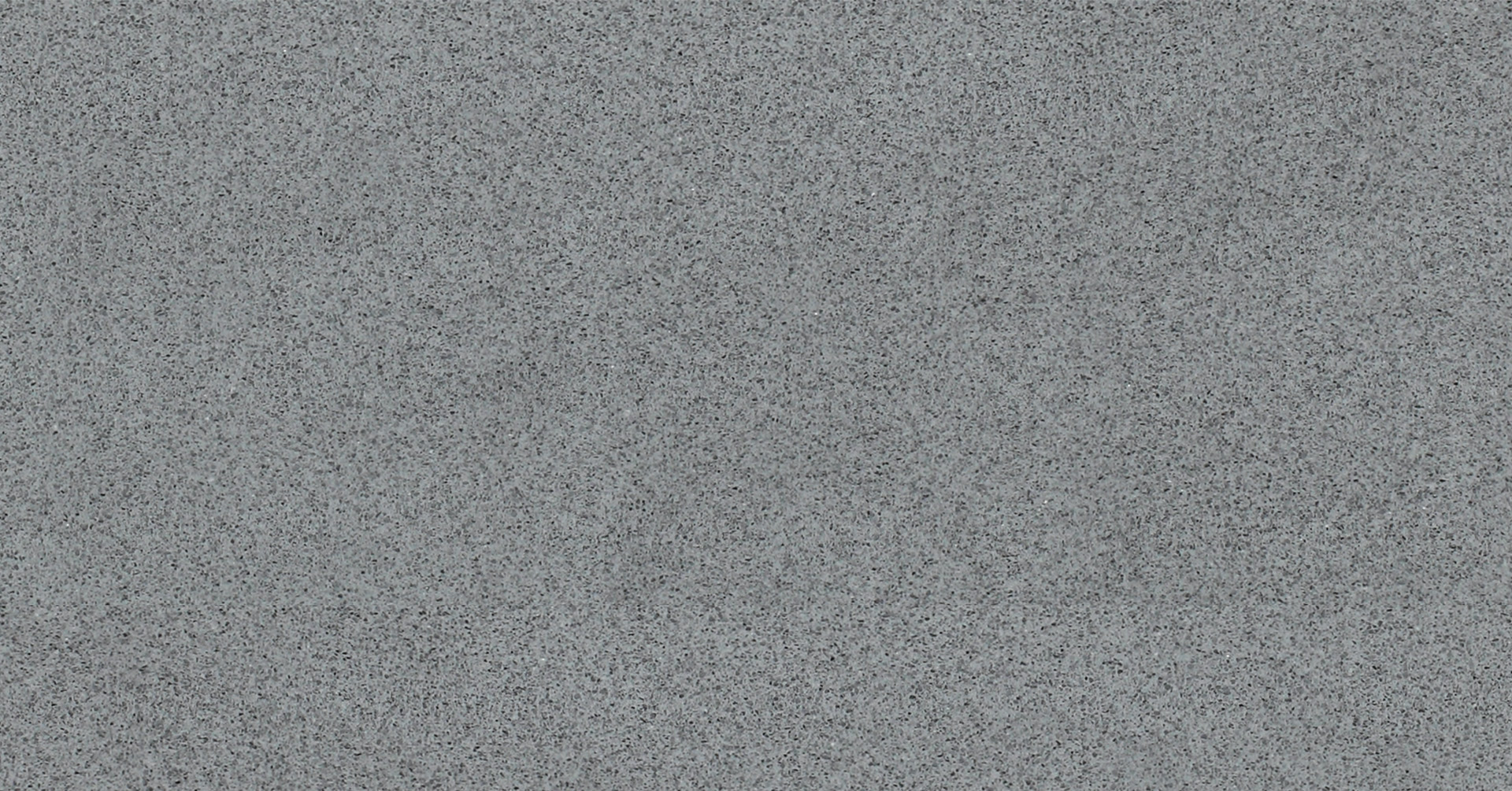

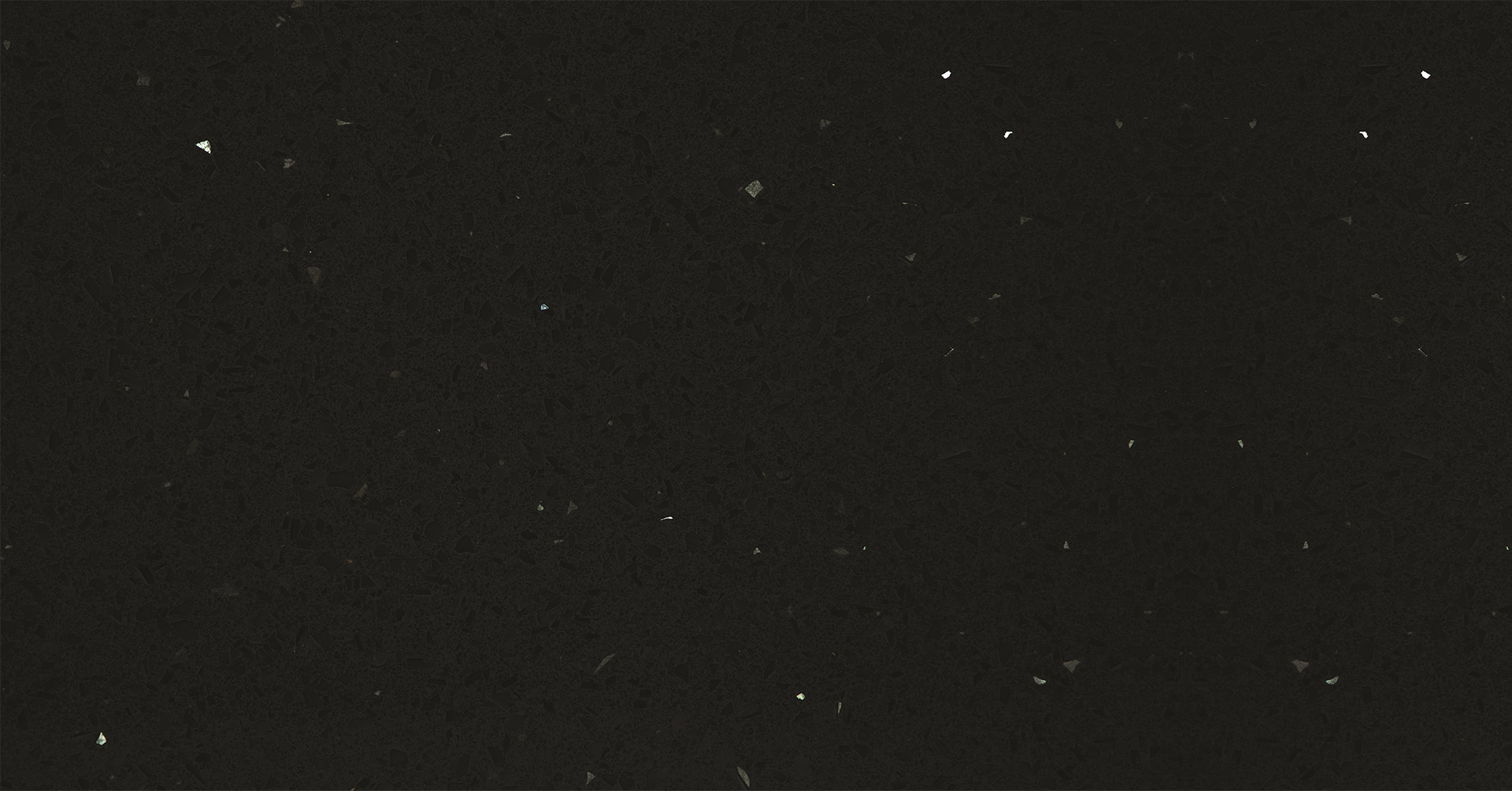

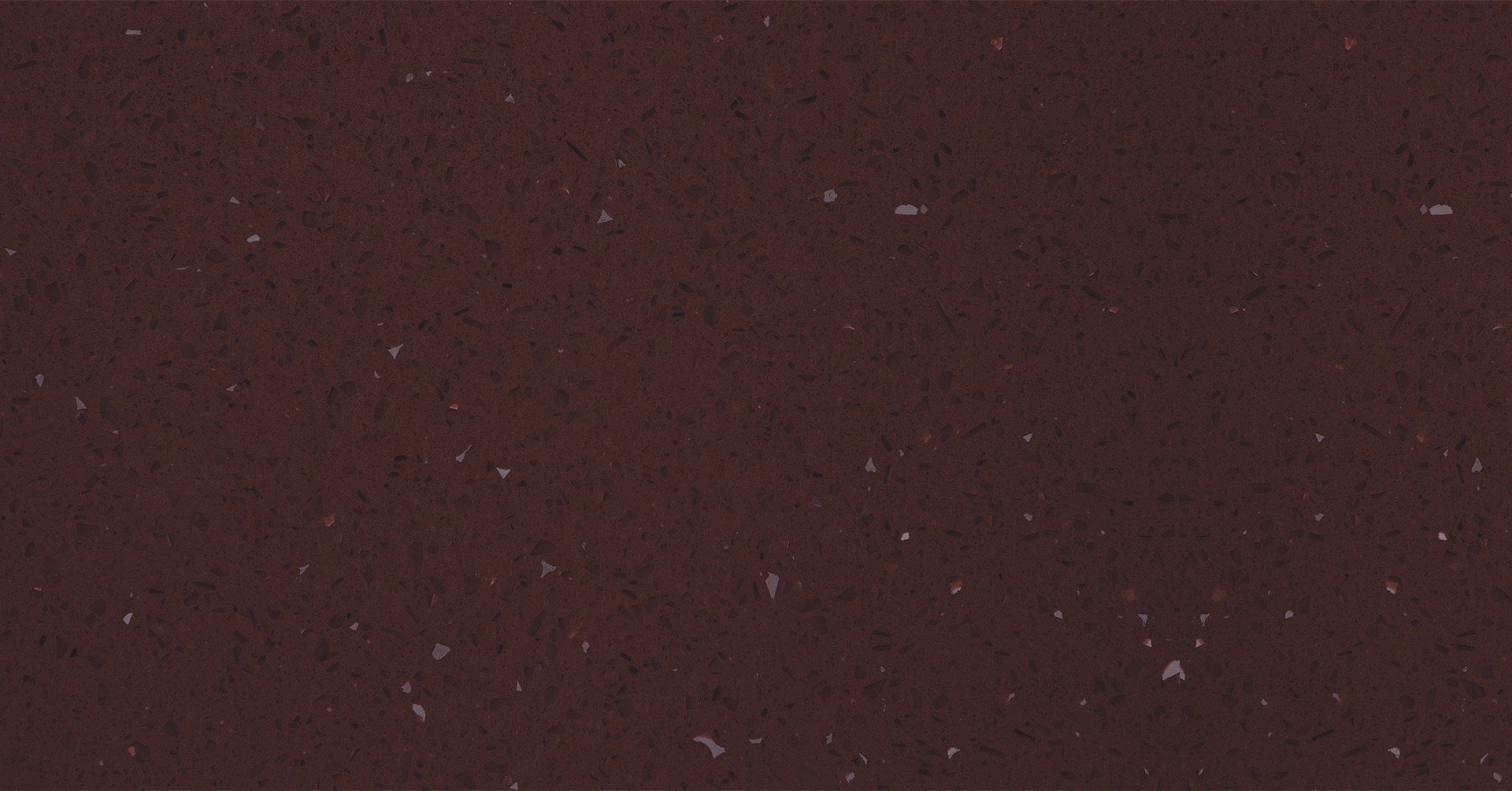

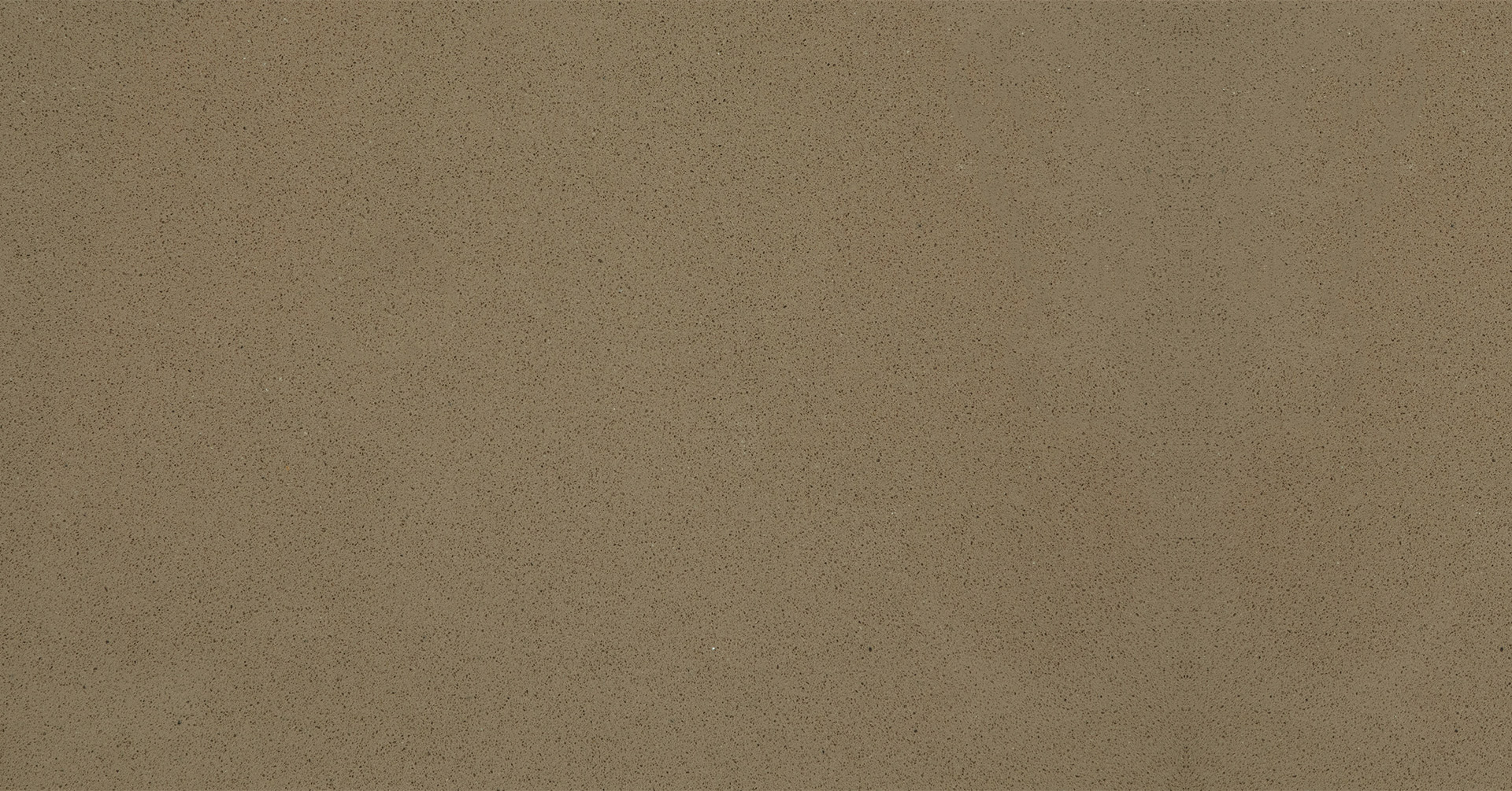

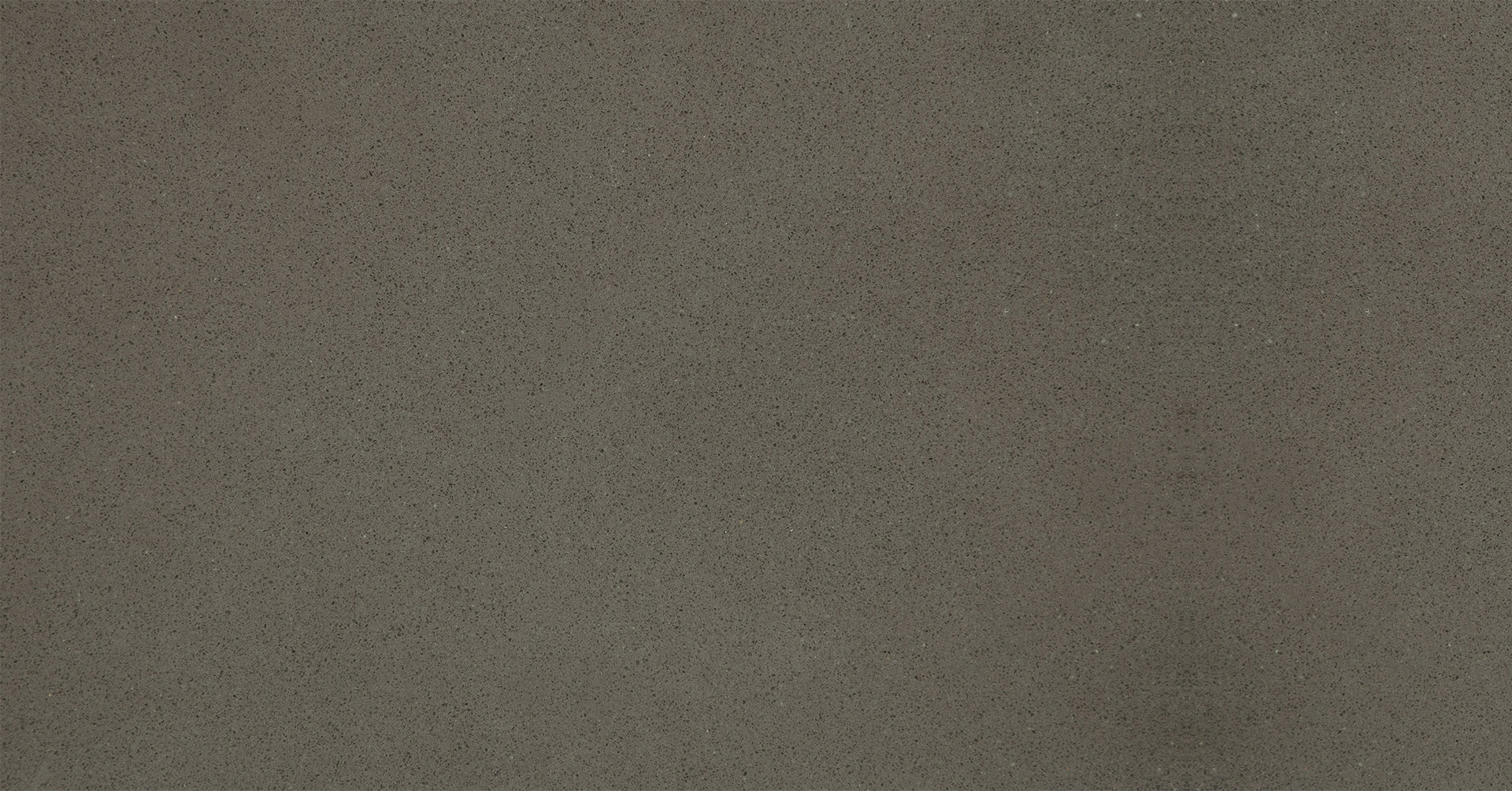

Engineered stone is a composite material that is made out of crushed stone grouped together by some form of adhesive. Engineered or composite stone has a wide range of applications across multiple industry verticals. With respect to kitchen counters, slabs are prepared out of quartz crystals that are bound together with the help of a resin binder. Most quartz is designed featuring a ratio of around 93 percent of crushed stone to 7 percent of pigmentation and resin.

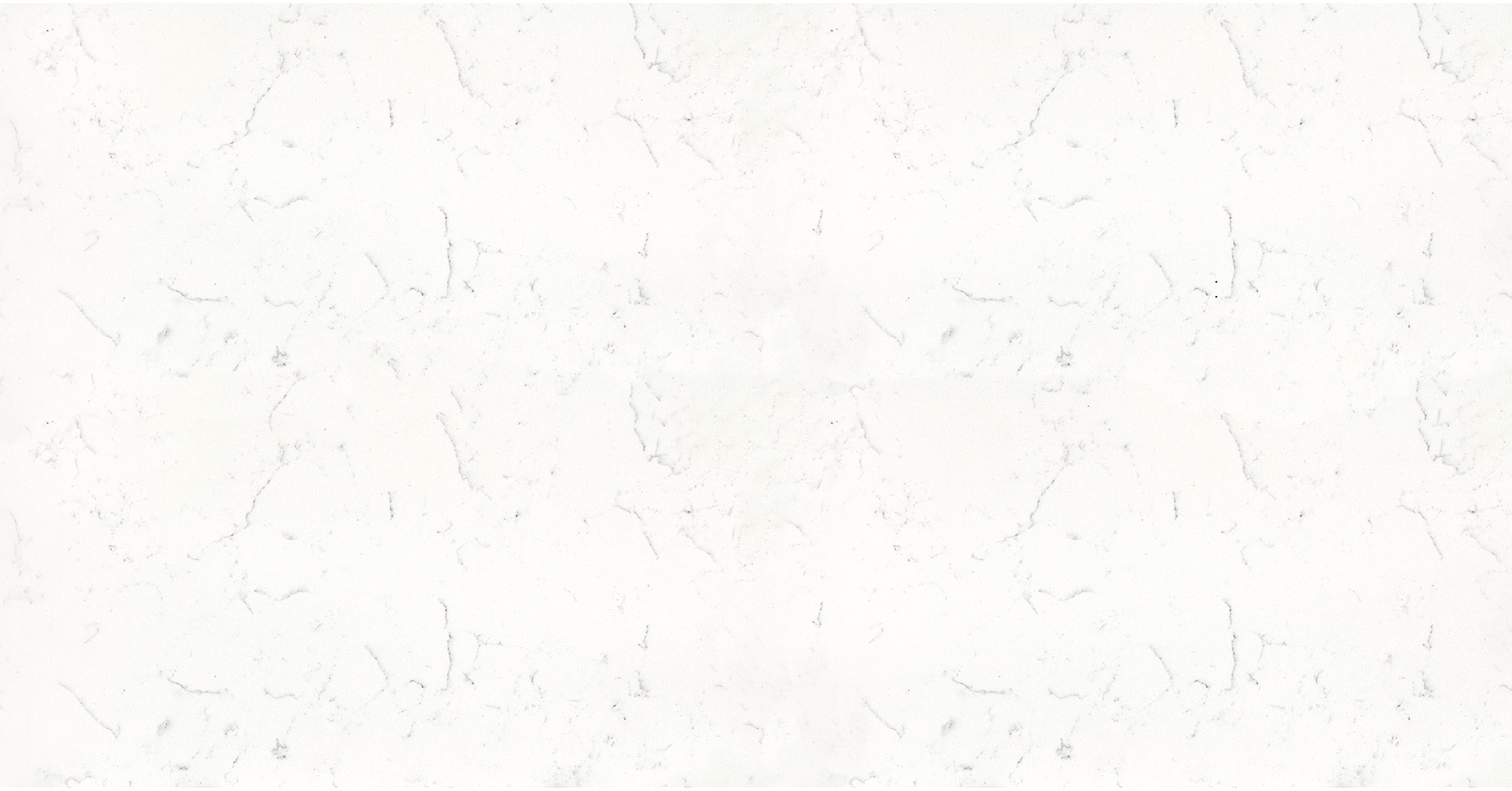

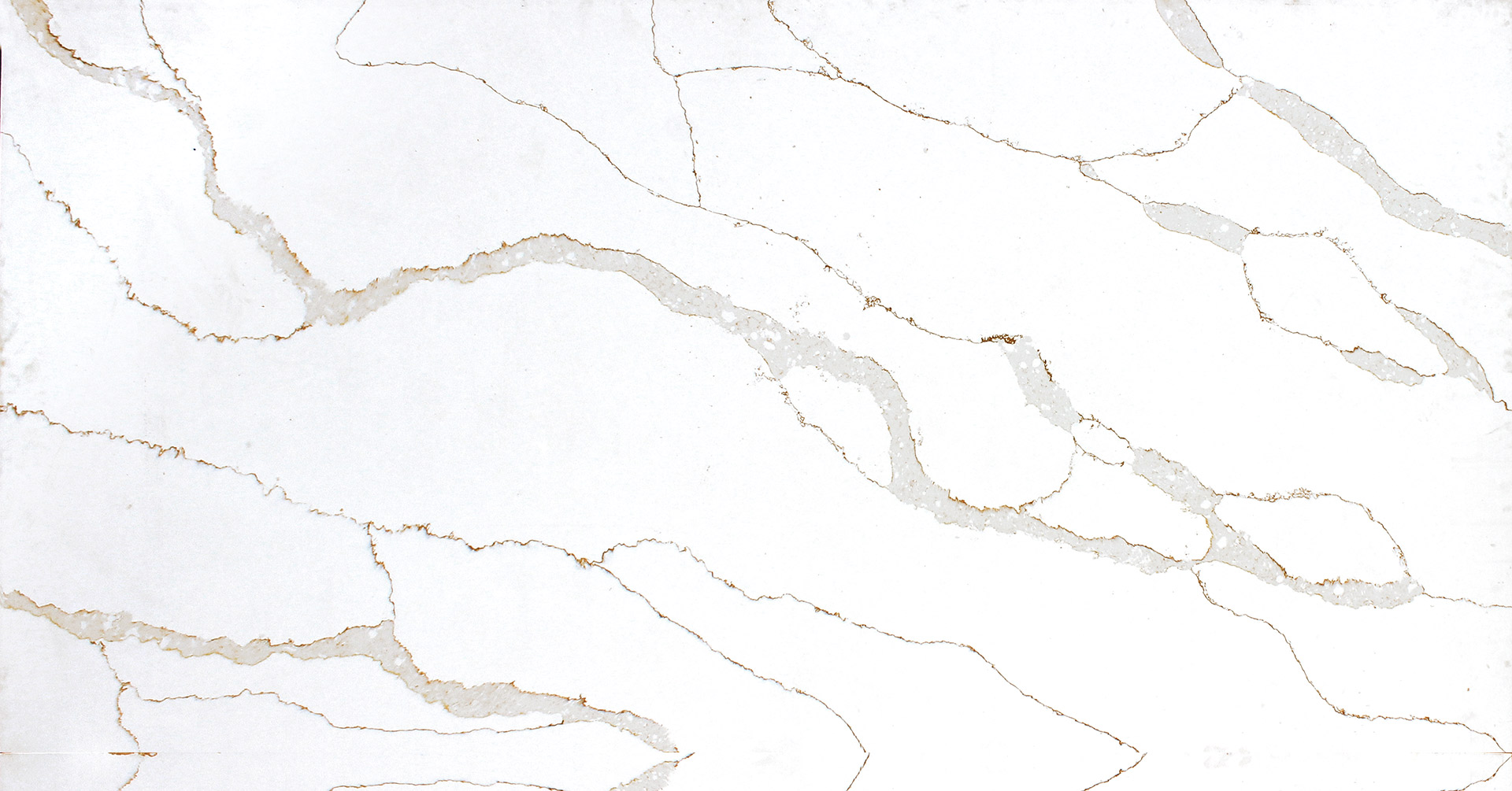

Engineered stone features a similar appearance to that of natural stone. The only difference is that engineered stone tends to be more uniform in pattern and color throughout. Natural stone will feature multiple variations in patterns, hues, and colors. As engineered marble or quartz is prepared artificially, the appearance of every marble slab will be the same with minimal variations.

Our Products

Johnson engineered stone products are undisputedly the most versatile and practical building material; truly nature redefined.

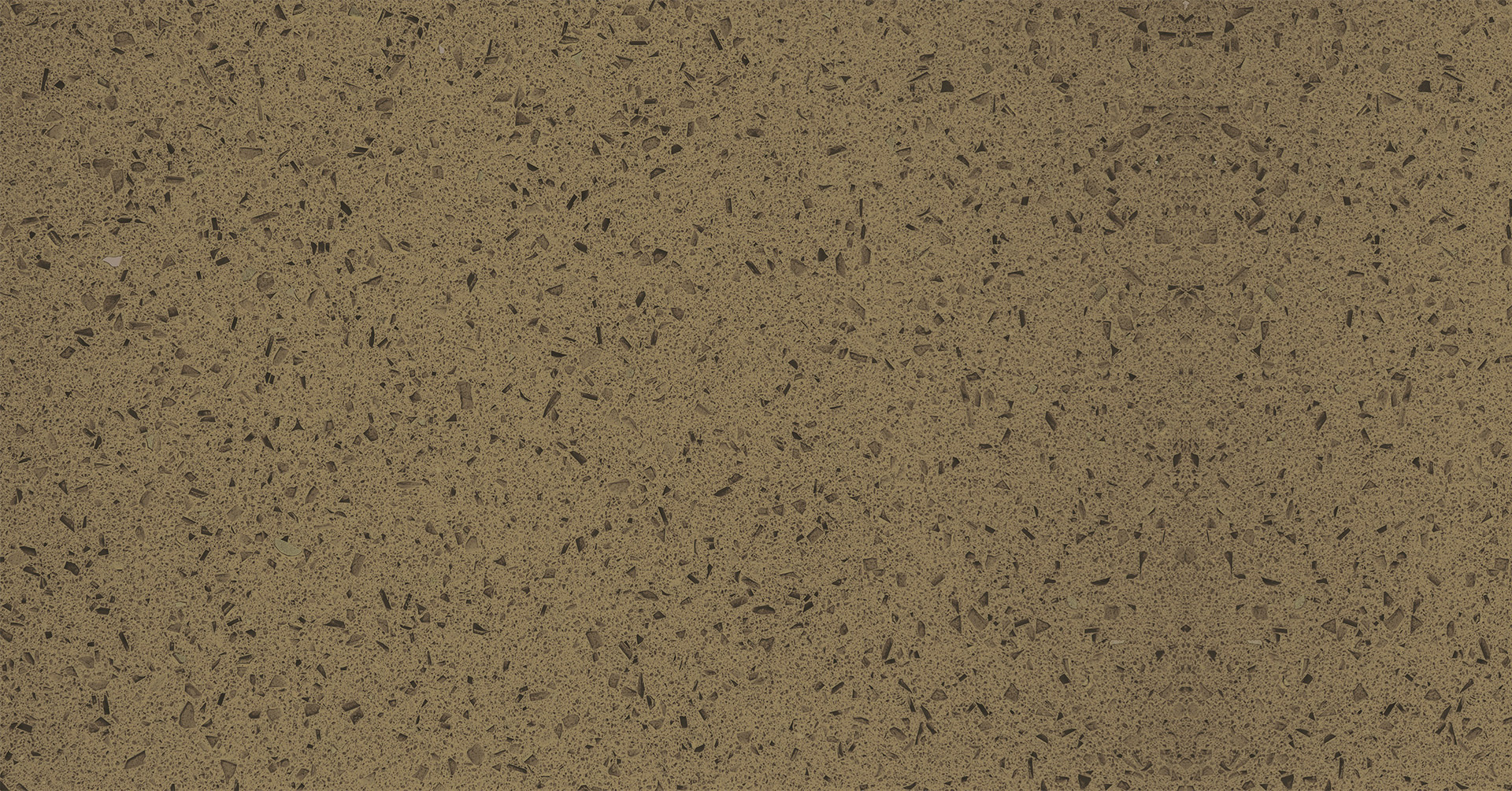

Engineered Quartz

Topshield

Beauty of natural stone untouched by germs. Presenting Topshield, India's 1st germ free Quartz kitchen countertops.

Quickstairs

Johnson Readymade Products offers the consumers an affordable alternative to natural marble, while maintaining a greater level of color consistency & strength.

Elemente

Johnson Marble & Quartz, a range of engineered stones, present ELEMENTE′ - the everlasting design expressions of mosaic captured in engineered stone.

Advantages of Engineered Stone

Engineered stones possess benefits that might not be available with natural counterparts. Some of the benefits of using engineered stone for your next home decor project are:

Engineered stone countertops are highly attractive

Engineered stone counters wear quite well

It is easier to clean the surfaces made out of composite stone

Surfaces will not stain easily

You get access to a myriad of options -ranging from colors to patterns, designs, styles

Use & Applications of Engineered Stone

Engineered stones are created by combining around 93 percent natural stone material with 7 percent enhanced pigments, polymer resins, and aggregates. The process imparts a stunning stone surface with excellent stain, heat, chip, and scratch resistance. Therefore, composite stone finds its applications in multiple areas including:

Why Choose Johnson Marble & Quartz?

Engineered stone surfaces by Johnson Marble & Quartz are designed to elevate living. With a blend of amazing designs, patterns, and colors, we are committed to enriching life experiences. We work with industry experts and excellent trade partners to deliver the highest quality of hard surfaces for any project. You can choose us for:

Reliability of services

100% customer

satisfaction

Expert team of interior

designers, architects,

and fabricators

Several years of industry

relevant experience

Leading Engineered Quartz and Marble Manufacturer

Johnson Marble & Quartz takes pride in being a pioneering manufacturer of world-class engineered marble and quartz hard surfaces. We introduce the innovative range of luxury slabs and other surfaces made out of engineered stone. Our stones or surfaces are available in multiple variations of thickness, finishes, colors, and sizes. We have been awarded with the Esteemed Superbrand Award for the third time in a row.

The place where ideas become a REALITY

The brand Johnson Marble & Quartz is a result of our innovative product designs and development initiatives.

Nature Oriented

- Inspired by the unprecedented beauty of natural marble, the Johnson Marble & Quartz product-line bridges the gap between nature and technology by maintaining the look and feel of natural marble while eliminating all the inherent problems that are prevalent in natural products.

Innovation

- Innovation has always run in the veins of H & R Johnson. A determination to push the boundaries, challenge the ordinary and exceed expectations has led to the birth of one of the most revolutionary products – Engineered Marbles and Quartz.

Germ Free

- India’s first and only quartz surface, Top Shield is an invisible layer of Johnson’s patented technology that keeps your kitchen perfectly germ-free.

GreenGuard

- Johnson is proud to announce the prestigious UL GREENGUARD GOLD Certification and solidifying a vision for sustainable future. We have always been forefront in adopting innovations and eco-friendly alternatives for developing our products.

The Superbrand For Your Super Spaces!

- Johnson has received the prestigious Superbrands India Consumer Validated seal 2023 which reinforces that we are the most valuable brand in the mind of consumers across India.

FAQ's

Engineered stone is extremely durable and hard -almost equivalent to granite. When installed properly, engineered stone is less vulnerable to scratches or other damages.

It will vary depending on your specific requirements. Still, you can expect the price to start at 220 INR per square feet.

Engineered stones are stain-resistant.

Engineered stone is a type of composite material designed with crushed stone and bound together by some adhesive.

Engineered stone is a mixture of some natural stone like quartz combined with additives, aggregated pigments, or resin binders.

Engineered stones are cut professionally by dedicated machines.

No. engineered stone is stain-resistant.

Yes. Engineered stone is known for its durability.